In the modern poultry industry, ensuring the health and quality of chicks begins at the poultry hatchery. The chick incubation process plays a crucial role in determining the overall productivity and efficiency of poultry farming. At Skylark, our commitment to innovation and advanced hatchery technology ensures that every chick receives the best possible start in life.

Understanding Poultry Hatcheries

A poultry hatchery is a specialized facility where fertile eggs are incubated under controlled conditions until they hatch into healthy chicks. The quality of a hatchery directly affects the survival rate, growth, and long-term productivity of poultry. By implementing cutting-edge hatchery technology, Skylark has revolutionized the egg hatching process, ensuring the highest hatchability rates and chick quality.

The Egg Hatching Process: A Science-Driven Approach

The egg hatching process is a delicate procedure that requires precision and expertise. Skylark follows a systematic approach to ensure optimal conditions for embryo development:

- Egg Selection & Fertility Testing: Only high-quality, fertile eggs are selected for incubation. This ensures that only viable embryos progress through the chick incubation phase.

- Temperature & Humidity Control: Eggs are placed in incubators with controlled temperature and humidity levels, which are crucial for proper embryonic development.

- Egg Turning: Automated systems gently turn the eggs at regular intervals to prevent the embryo from sticking to the shell membrane.

- Candling & Monitoring: Throughout the egg hatching process, eggs are monitored using candling techniques to track embryo development and detect any abnormalities.

- Hatching & Chick Grading: After 21 days, chicks begin to hatch. At Skylark, we use advanced grading systems to ensure that only healthy, strong chicks are sent to farms.

Cutting-Edge Hatchery Technology at Skylark

Skylark integrates modern hatchery technology to optimize efficiency and chick health. Our facilities are equipped with:

- Automated Incubators: Ensuring precise temperature and humidity control for uniform embryo development.

- High-Efficiency Ventilation Systems: Maintaining optimal air quality for enhanced chick viability.

- Biosecurity Measures: Reducing the risk of infections and ensuring disease-free poultry hatchery operations.

- Data Analytics & AI Integration: Continuous monitoring and adjustments based on real-time data for improved hatch rates.

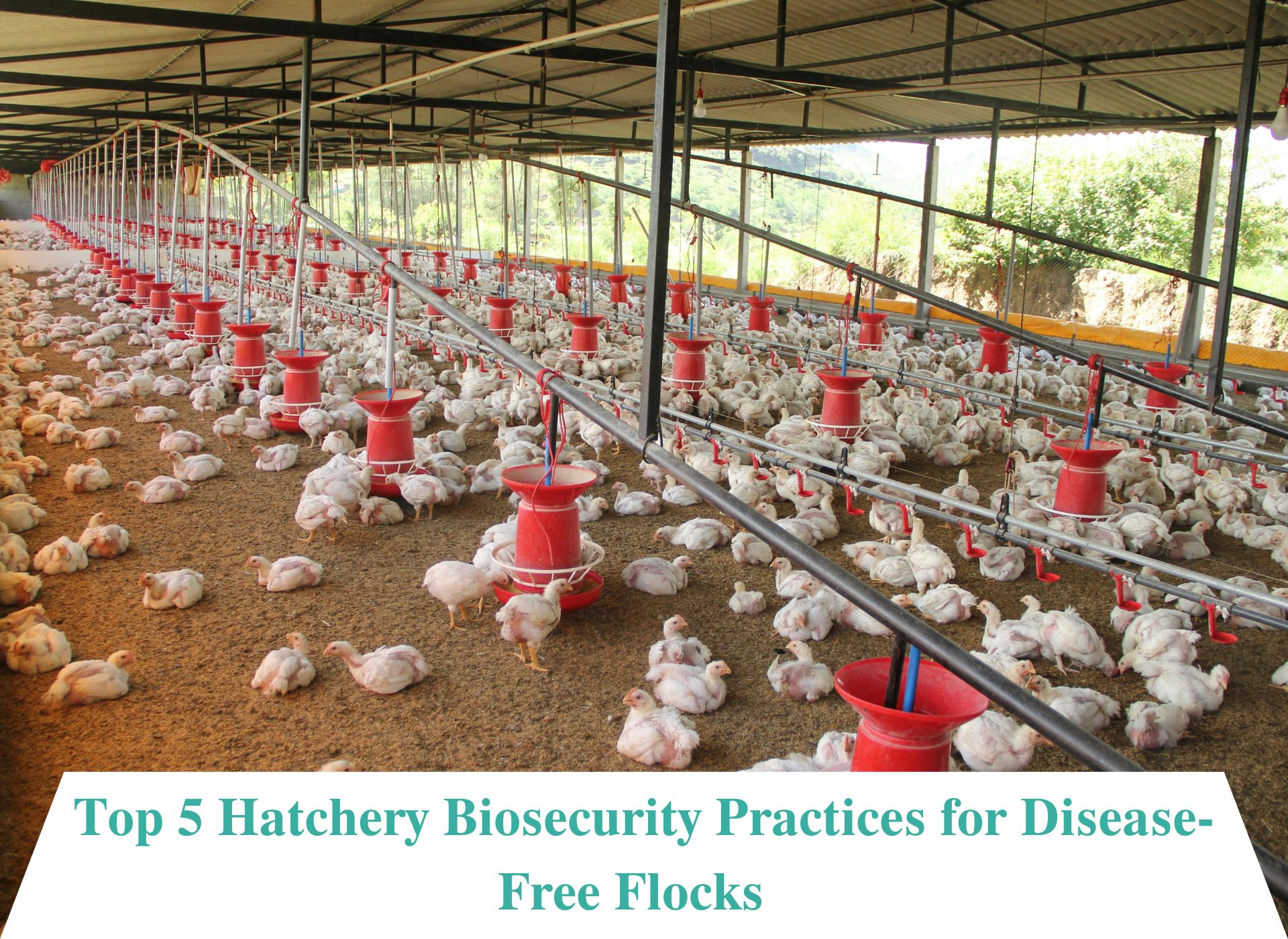

Importance of Biosecurity in Poultry Hatcheries

Biosecurity is a critical component of high-quality poultry hatchery management. At Skylark, strict protocols are in place to prevent contamination and disease outbreaks:

- Sanitized Facilities: Regular cleaning and disinfection of all hatchery equipment.

- Strict Entry Controls: Limited access to hatchery areas to prevent contamination.

- Vaccination Programs: Ensuring chicks are protected from common poultry diseases.

- Health Monitoring: Regular testing of breeder flocks and hatchery operations.

The Role of Nutrition in Chick Incubation & Early Growth

Nutrition plays a vital role in the chick incubation process and early chick development. Proper feeding during the embryonic stage enhances chick vitality and growth performance. Skylark ensures:

- Balanced Breeder Diets: High-quality feed for breeder hens to produce nutrient-rich eggs.

- Pre-Hatch Nutrition Enhancement: Enriching hatching eggs with essential nutrients for stronger chick development.

- Post-Hatch Feeding Strategies: Providing immediate access to nutrient-dense feed to enhance chick growth and immunity.

Benefits of Skylark’s Hatchery Technology for Poultry Farmers

Farmers who source chicks from Skylark’s poultry hatchery experience numerous benefits:

- Higher Hatchability Rates: Advanced hatchery technology results in better embryo survival and stronger chicks.

- Healthier Chicks: Reduced risk of early mortality and diseases.

- Enhanced Growth Performance: Chicks with better weight gain and feed conversion efficiency.

- Increased Profitability: Stronger, disease-resistant chicks lead to improved farm productivity and higher returns.

Future Innovations in Hatchery Technology

Skylark continues to invest in research and development to enhance hatchery technology. Future advancements include:

- AI-Powered Incubation Systems: Enhancing precision in temperature and humidity control.

- Smart Biosecurity Solutions: Using sensors and automation to detect and prevent contamination.

- Genetic Selection Programs: Improving chick quality through advanced breeding techniques.

Conclusion

A high-quality poultry hatchery is the foundation of a successful poultry farming operation. With Skylark’s commitment to innovation, biosecurity, and precision in the egg hatching process, we ensure the production of healthy, strong chicks. Our state-of-the-art hatchery technology and expert-driven chick incubation techniques set us apart as a leader in the poultry industry. By continuously evolving and integrating the latest scientific advancements, Skylark remains dedicated to revolutionizing poultry farming and supporting farmers worldwide.