Ensuring freshness in poultry products is a critical aspect of the poultry industry, impacting both consumer health and satisfaction. From farm to fork, every step in the poultry production chain must be meticulously managed to maintain the highest quality standards. In this blog, we will explore the journey of poultry products from the farm to the consumer’s table and the key measures taken to ensure their freshness.

The Importance of Fresh Poultry Products

Fresh poultry products are not only more flavorful but also safer for consumption. Ensuring freshness helps to:

- Maintain nutritional value

- Reduce the risk of contamination

- Enhance taste and texture

- Improve consumer trust in poultry brands

Key Factors Affecting Poultry Freshness

Several factors influence the freshness of poultry products, including:

- Farm Management Practices – Healthy birds produce high-quality meat.

- Processing and Packaging – Hygienic handling and airtight packaging prevent spoilage.

- Cold Chain Logistics – Maintaining optimal temperatures from farm to store ensures freshness.

- Consumer Handling – Proper storage at home extends product shelf life.

The Farm-to-Fork Journey of Poultry Products

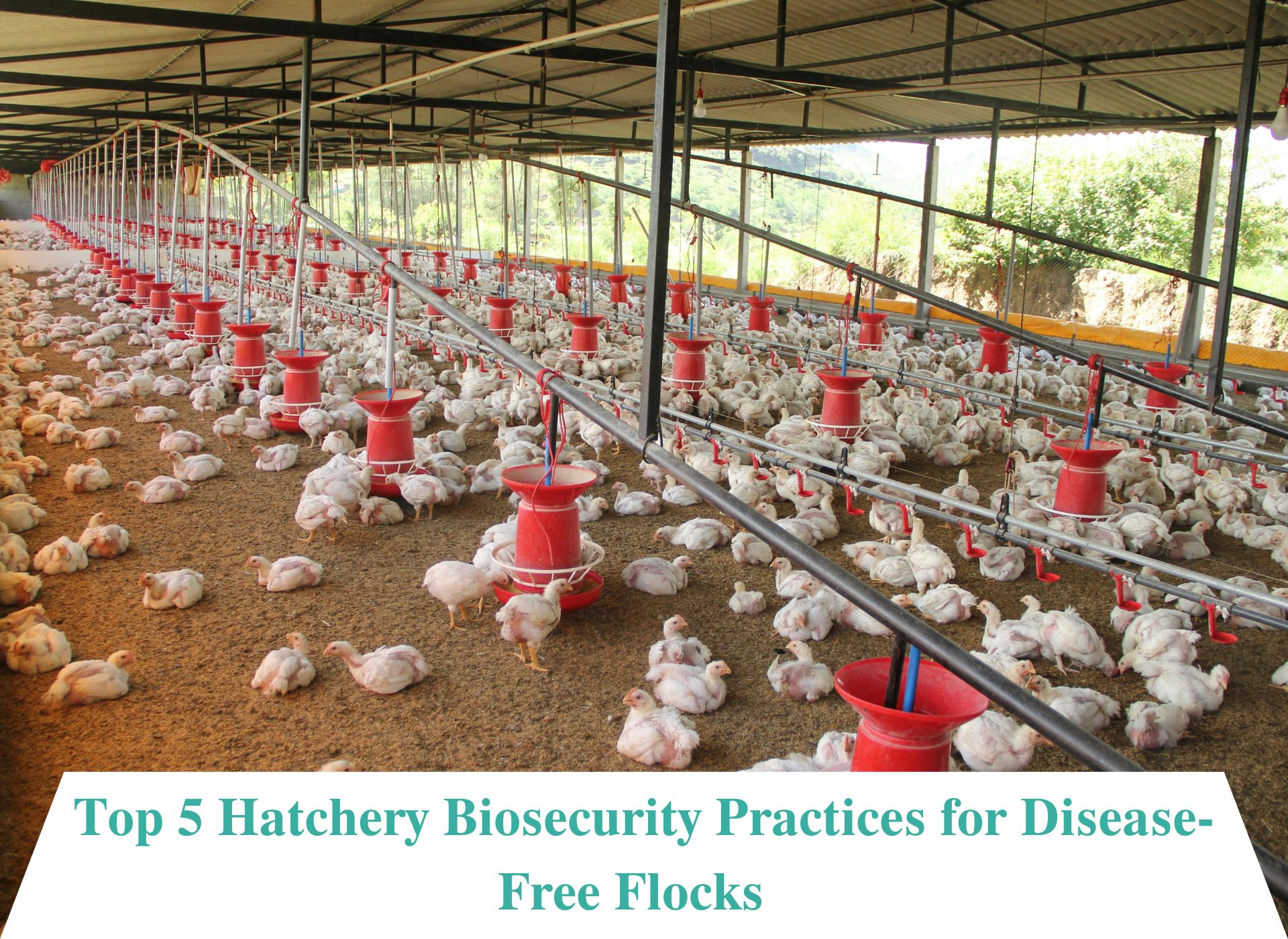

1. Raising Healthy Poultry on the Farm

The journey of fresh poultry products begins at the farm. Ensuring healthy bird growth is crucial for producing high-quality meat. Factors that contribute to this include:

- Balanced Nutrition – Poultry is fed nutrient-rich diets to promote healthy growth.

- Disease Prevention – Regular health check-ups and vaccinations reduce disease risks.

- Proper Housing – Clean, well-ventilated, and stress-free environments enhance bird welfare.

2. Hygienic Processing and Slaughtering

Once the birds are ready for processing, strict hygiene measures are followed to maintain freshness:

- Sanitized Processing Units – Modern slaughterhouses use automated systems to minimize contamination.

- Rapid Chilling Methods – Poultry meat is quickly cooled to prevent bacterial growth.

- Stringent Quality Checks – Every batch undergoes inspection to ensure safety and quality.

3. Advanced Packaging Techniques

Proper packaging plays a vital role in preserving the freshness of poultry products. Some effective packaging methods include:

- Vacuum Sealing – Removes oxygen to slow bacterial growth.

- Modified Atmosphere Packaging (MAP) – Uses gases like carbon dioxide to maintain freshness.

- Leak-Proof and BPA-Free Materials – Prevents contamination and extends shelf life.

4. Maintaining the Cold Chain

The cold chain is crucial in ensuring that poultry products remain fresh until they reach consumers. Key elements include:

- Refrigerated Transport – Temperature-controlled trucks prevent spoilage.

- Cold Storage Facilities – Warehouses maintain optimal storage conditions.

- Real-Time Monitoring – Sensors track temperature fluctuations to prevent quality loss.

5. Retail and Consumer Handling

Even after poultry products reach supermarkets and stores, maintaining freshness is essential. Best practices include:

- Proper Display and Storage – Supermarkets store poultry in temperature-controlled sections.

- Consumer Education – Labels provide storage instructions to buyers.

- Immediate Refrigeration at Home – Consumers should store poultry at 0-4°C to maintain freshness.

How Skylark Foods Ensures Freshness in Poultry Products

Skylark Foods is dedicated to delivering the freshest poultry products by implementing advanced technologies and strict quality control measures. Here’s how they stand out:

1. High-Quality Feed for Healthy Growth

Fresh poultry starts with healthy birds. Skylark Foods provides premium feed to ensure optimal poultry nutrition and meat quality.

2. State-of-the-Art Processing Facilities

Modern slaughterhouses with strict hygiene standards help maintain the highest level of freshness and safety in poultry products.

3. Advanced Cold Chain Management

Skylark Foods uses cutting-edge refrigeration and transport systems to keep poultry products fresh from farm to store.

4. Sustainable and Safe Packaging

Eco-friendly and BPA-free packaging solutions are used to ensure safe and long-lasting poultry freshness.

5. Quality Assurance at Every Stage

Each batch undergoes rigorous quality testing to ensure compliance with food safety standards before reaching consumers.

Conclusion

From farm to fork, ensuring the freshness of poultry products requires a combination of advanced farming practices, hygienic processing, effective packaging, and cold chain management. Skylark Foods is committed to delivering high-quality, fresh poultry products to consumers by following industry-leading practices. By maintaining strict hygiene, using advanced refrigeration, and ensuring proper handling, Skylark Foods guarantees that every poultry product reaching your plate is safe, nutritious, and delicious.