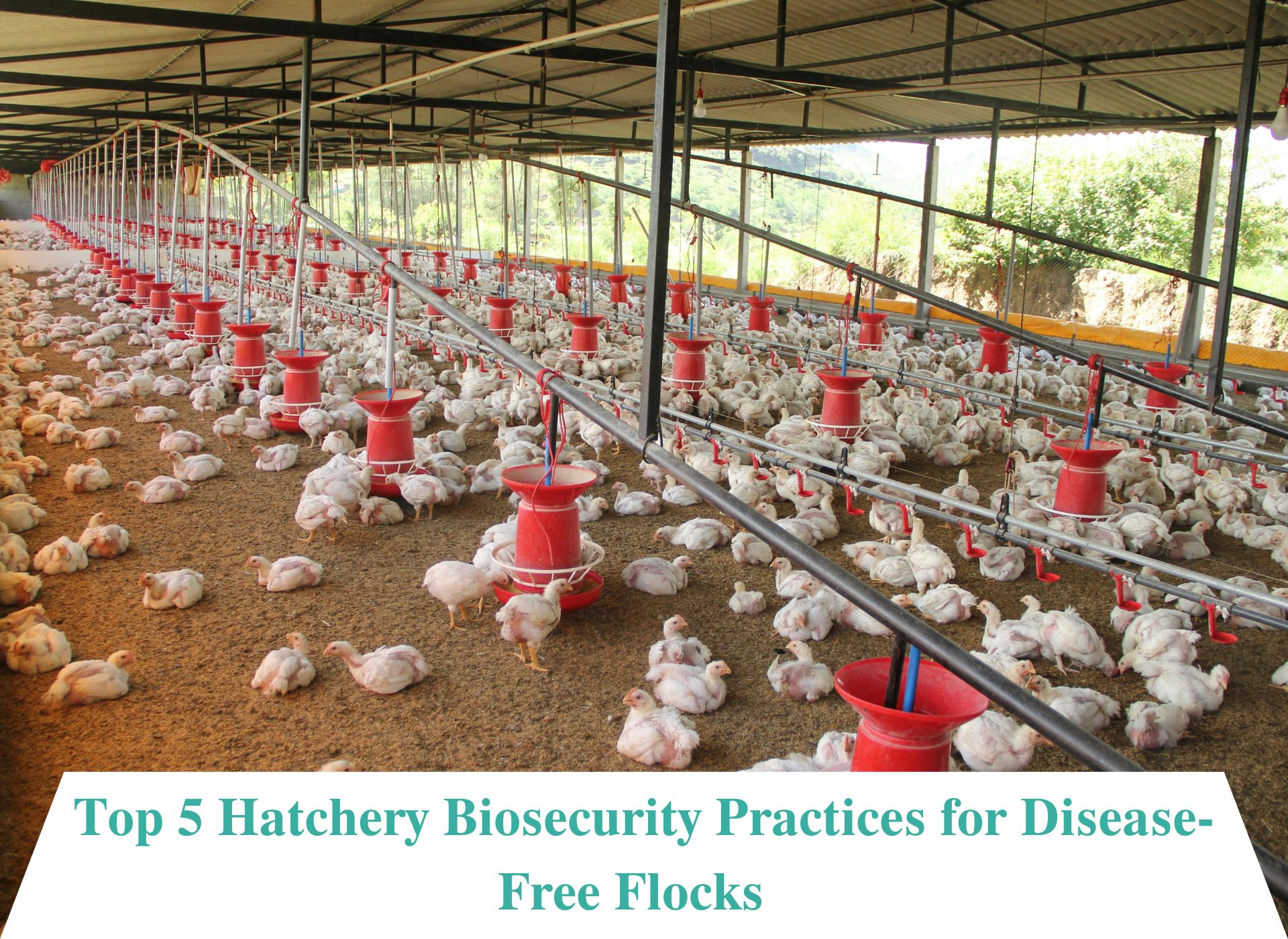

Biosecurity in poultry hatcheries is crucial for preventing disease outbreaks and ensuring the health of chicks. Effective hatchery biosecurity measures not only protect poultry farms from devastating infections but also contribute to a more sustainable and profitable poultry industry. In this blog, we explore how biosecurity in hatcheries plays a vital role in producing disease-free chicks and the key strategies used to maintain high standards of hygiene and safety.

Understanding Hatchery Biosecurity

Hatchery biosecurity refers to the preventive measures taken to protect eggs, chicks, and hatchery facilities from disease-causing pathogens. These measures are essential for minimizing the risk of contamination and ensuring the production of healthy, robust chicks. The key components of hatchery biosecurity include:

- Strict hygiene protocols

- Controlled environmental conditions

- Effective vaccination programs

- Restricted access to hatchery areas

- Regular disease monitoring and testing

The Importance of Biosecurity in Poultry Hatcheries

Biosecurity in poultry hatcheries is essential for several reasons:

- Prevention of Disease Outbreaks – Infections like avian influenza, Newcastle disease, and salmonella can spread rapidly in hatcheries, leading to high mortality rates.

- Improved Chick Health and Growth – Disease-free chicks have better survival rates and higher productivity.

- Enhanced Farm Profitability – Healthy chicks reduce the need for antibiotics and medical treatments, lowering production costs.

- Compliance with Industry Standards – Hatcheries must adhere to national and international biosecurity regulations to ensure safe poultry production.

Key Hatchery Biosecurity Measures

1. Facility Design and Maintenance

A well-designed hatchery plays a significant role in preventing disease transmission. Essential design features include:

- Separate clean and dirty areas – Prevents cross-contamination.

- Controlled ventilation systems – Reduces airborne disease risks.

- Drainage and waste disposal systems – Ensures proper removal of waste and contaminants.

- Regular facility disinfection – Hatchery equipment and surfaces are sanitized frequently.

2. Egg Handling and Incubation Hygiene

The egg hatching process is a critical stage where biosecurity measures must be strictly followed. Best practices include:

- Using only disease-free eggs – Sourced from certified, healthy breeder flocks.

- Sanitizing eggs before incubation – Reduces bacterial contamination.

- Maintaining optimal incubation conditions – Proper temperature and humidity prevent pathogen growth.

- Routine cleaning of incubators and hatchers – Minimizes disease spread.

3. Personnel and Visitor Control

Human movement in and out of hatcheries is a major biosecurity risk. To mitigate this:

- Staff must wear protective clothing and footwear

- Handwashing and disinfection stations are mandatory

- Visitors are restricted from sensitive areas

- Employees follow strict entry and exit protocols

4. Disease Monitoring and Testing

Routine health checks and laboratory testing help detect diseases early. Key steps include:

- Regular screening for common poultry diseases

- Testing breeder flocks for infections

- Immediate isolation of sick birds

- Maintaining accurate health records

5. Effective Vaccination and Medication Programs

Preventive vaccination programs are essential for producing disease-free chicks. Hatchery managers must:

- Administer vaccines at the right time

- Use high-quality, approved vaccines

- Ensure proper vaccine storage and handling

- Monitor vaccine effectiveness through health tracking

6. Post-Hatch Biosecurity and Chick Transport

Ensuring biosecurity doesn’t end at the hatchery—chick transport and farm placement are equally important. Strategies include:

- Transporting chicks in clean, disinfected vehicles

- Providing adequate ventilation during transport

- Delivering chicks to pre-cleaned, biosecure farms

- Minimizing stress during handling

How Skylark Hatcheries Ensure Disease-Free Chicks

Skylark Hatcheries is committed to the highest biosecurity standards to produce healthy, robust chicks. Their approach includes:

1. Advanced Hatchery Technology

Skylark Hatcheries uses cutting-edge hatchery technology, including automated egg handling, controlled incubation environments, and advanced ventilation systems to minimize contamination risks.

2. Strict Hygiene and Sanitation Protocols

Every step in the hatchery process follows rigorous hygiene measures. From egg collection to chick placement, Skylark ensures:

- Regular equipment sterilization

- Frequent air and water quality testing

- Proper waste management

3. Comprehensive Disease Prevention Programs

Skylark Hatcheries implements industry-leading vaccination protocols and disease monitoring strategies to prevent infections and maintain a disease-free flock.

4. Trained Biosecurity Personnel

The hatchery staff at Skylark undergo continuous biosecurity training to stay updated on the latest disease prevention techniques and industry regulations.

Conclusion

Hatchery biosecurity is the foundation of disease-free poultry production. By implementing strict hygiene practices, advanced hatchery technology, controlled incubation conditions, and effective vaccination programs, poultry hatcheries can minimize disease risks and improve chick health. Skylark Hatcheries stands out as a leader in biosecure poultry production, ensuring that every chick raised under its care meets the highest standards of health and quality. A strong biosecurity framework benefits not only the poultry industry but also ensures safe, high-quality poultry products for consumers worldwide.