Inside a Poultry Feed Mill: From Raw Grain to High-Performance Feed

When it comes to successful poultry farming, the quality of nutrition is paramount. Behind every healthy flock and productive farm is a well-formulated feed — and at the heart of this process is the poultry feed mill. At Skylark Group, an industry leader in integrated poultry operations, feed manufacturing is a fine science driven by innovation, precision, and quality.

In this blog, we’ll take you inside a modern poultry feed mill, explaining how raw grains are transformed into nutrient-rich, performance-enhancing poultry feeds. Whether you’re a farmer, enthusiast, or investor, understanding the feed manufacturing process gives you a clearer picture of why choosing the right poultry feed supplier matters.

Step 1: Raw Material Sourcing

The journey begins with sourcing high-quality raw materials. Skylark’s feed division ensures only the best grains like maize, soybean meal, and wheat bran make it to the poultry feed mill. Additives like vitamins, minerals, amino acids, and enzymes are also selected based on strict quality parameters.

As one of India’s top poultry feeds manufactures, Skylark is committed to sustainability. Wherever possible, raw materials are locally sourced to reduce transportation emissions and support regional farming communities. Each batch undergoes rigorous quality testing for moisture, mycotoxins, and nutritional profile before being approved.

Step 2: Cleaning and Grinding

Once the materials arrive at the poultry feed mill, they undergo cleaning to remove dust, stones, and other impurities. This is crucial because contaminants can reduce feed quality and pose health risks to poultry.

After cleaning, grains are ground into a fine powder using hammer mills. The grinding process is carefully controlled — a uniform particle size ensures that birds can easily digest the feed. This step plays a key role in enhancing feed conversion ratios, a focus area for every leading poultry feed supplier.

Step 3: Batching and Mixing

Now comes the precision part — batching. Every ingredient is weighed accurately as per the feed formulation. Skylark’s feed mills are equipped with automated batching systems that eliminate human error and guarantee consistency.

The ingredients are then transferred to industrial mixers where they are blended thoroughly. As one of the most trusted poultry feeds manufactures, Skylark ensures homogeneity in every batch. Uniform mixing means every pellet or mash contains the same level of nutrients, which directly impacts bird growth, immunity, and productivity.

Step 4: Conditioning and Pelletizing

Once the mix is ready, it is sent for conditioning. In this phase, steam is introduced to soften the material. Conditioning enhances pellet quality, digestibility, and shelf life — vital traits of high-performance poultry feeds.

The conditioned mix is then passed through pellet mills. Here, it is compressed into cylindrical shapes (pellets) under high pressure. The size of pellets is adjusted based on the type and age of the bird — chicks, growers, and layers all have different feed requirements. Skylark’s expertise as a poultry feed supplier ensures that feed formulations and pellet sizes are customized for every growth phase.

Step 5: Cooling and Crumbling

Freshly pelletized feed is hot and moist — which makes it vulnerable to mold growth. So, it is passed through coolers to reduce temperature and moisture content. This ensures durability and safety during storage and transport.

For chicks and small birds, feed is crumbled into smaller pieces. Skylark’s modern poultry feed mill lines are equipped with high-efficiency crumbler machines that deliver consistent particle sizes, ideal for better intake and digestion in young poultry.

Step 6: Quality Control and Lab Testing

Every batch of feed undergoes strict quality control checks in Skylark’s in-house laboratories. Parameters like protein content, moisture level, fat, fiber, and toxin levels are tested to ensure compliance with nutritional standards.

Being one of the few fully integrated poultry feeds manufactures with advanced lab facilities, Skylark guarantees premium-quality poultry feeds that consistently deliver results. This is why Skylark is trusted as a long-term poultry feed supplier by farmers across India.

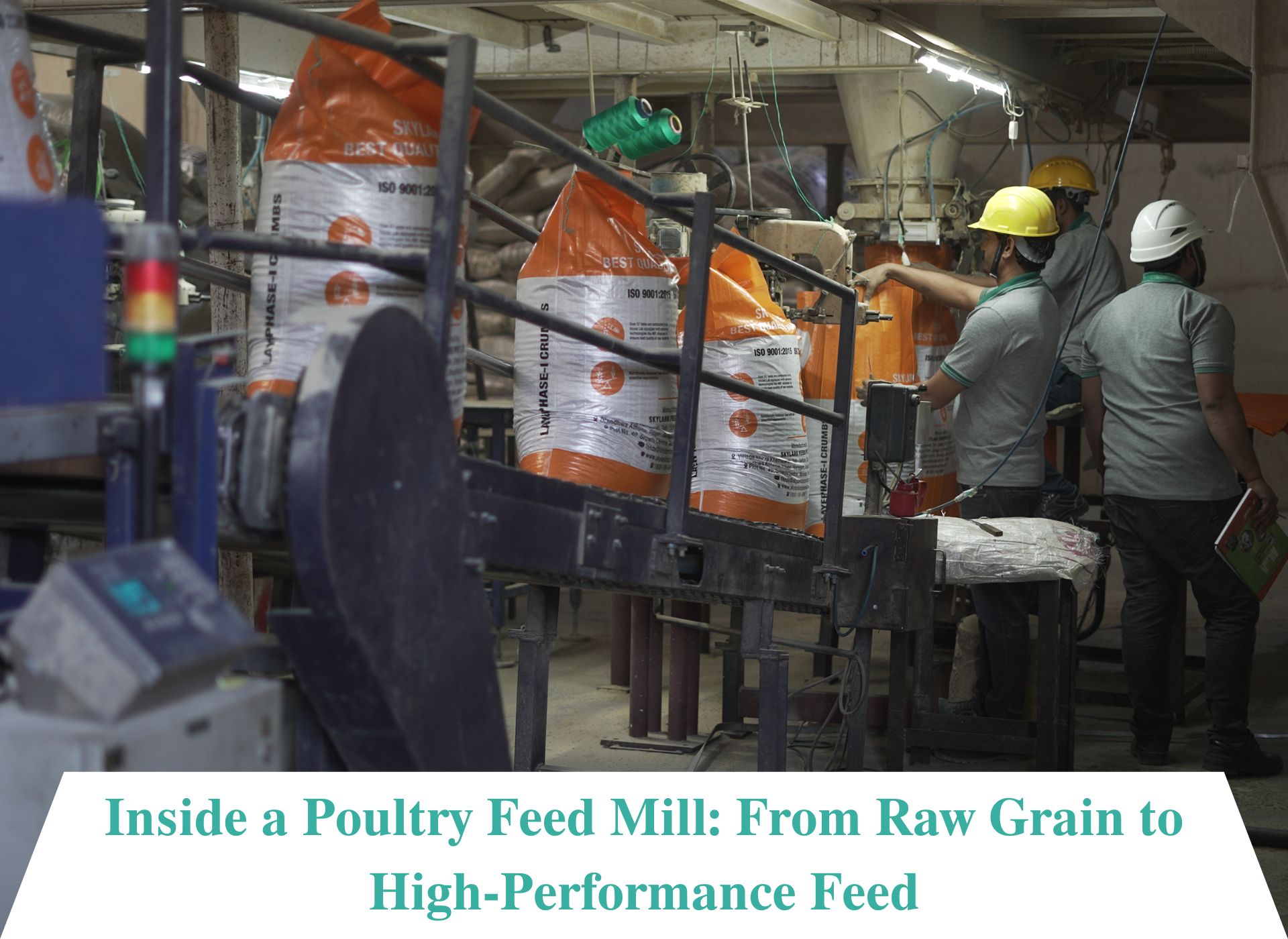

Step 7: Packaging and Distribution

Once the feed passes all tests, it is packed using automated systems in moisture-proof bags. These bags are clearly labeled with product information, usage guidelines, and manufacturing details.

As a full-scale poultry feed supplier, Skylark has an efficient distribution network that ensures timely delivery to farms, dealers, and franchises. Whether in remote villages or urban poultry hubs, Skylark’s poultry feeds are easily accessible to customers nationwide.

Why the Poultry Feed Mill Matters

A poultry feed mill is not just a production unit — it’s the engine that powers modern poultry farms. From raw grain selection to precision batching and automated quality control, each step plays a vital role in producing safe, efficient, and nutritious poultry feeds.

Farmers who choose Skylark as their poultry feed supplier benefit from years of research, technical expertise, and innovation. This commitment makes Skylark one of the most dependable poultry feeds manufactures in India.

Sustainable & Scientific Feed Production

Sustainability is deeply embedded in Skylark’s operations. Waste materials from the poultry feed mill are recycled or converted into organic fertilizers. Energy-efficient machinery, water-saving systems, and eco-friendly packaging make the entire process more sustainable.

As responsible poultry feeds manufactures, Skylark continuously upgrades its feed production facilities with the latest technologies. This not only improves output but also ensures environmental responsibility.

Conclusion: The Backbone of Poultry Success

Inside every bag of feed is a story of science, care, and innovation. The poultry feed mill is where nutrition strategies come to life, and it’s where Skylark’s commitment to quality truly shines. For farmers looking to optimize flock health, growth, and profitability, the choice of poultry feed supplier makes all the difference.

As a pioneer among India’s leading poultry feeds manufactures, Skylark Feed brings unmatched value, reliability, and performance to every farm it serves. With a legacy of trust and a future driven by technology, Skylark continues to set the standard for modern poultry nutrition.

FAQ’s

Q1. What is a poultry feed mill?

A poultry feed mill is a facility where raw grains and nutrients are processed into formulated poultry feeds for different bird stages.

Q2. Why is the poultry feed mill important in poultry farming?

It ensures the production of consistent, high-quality feed that supports bird health, immunity, and growth efficiency.

Q3. What makes Skylark a leading poultry feed supplier?

Skylark uses advanced technology, strict quality control, and sustainable sourcing, making it a trusted poultry feed supplier in India.

Q4. How do poultry feeds impact bird performance?

Balanced poultry feeds enhance digestion, immunity, and growth, resulting in healthier, more productive flocks.

Q5. What raw materials are used in poultry feeds?

Common ingredients include maize, soybean meal, wheat bran, vitamins, minerals, and essential amino acids.